SulphurPro® Details

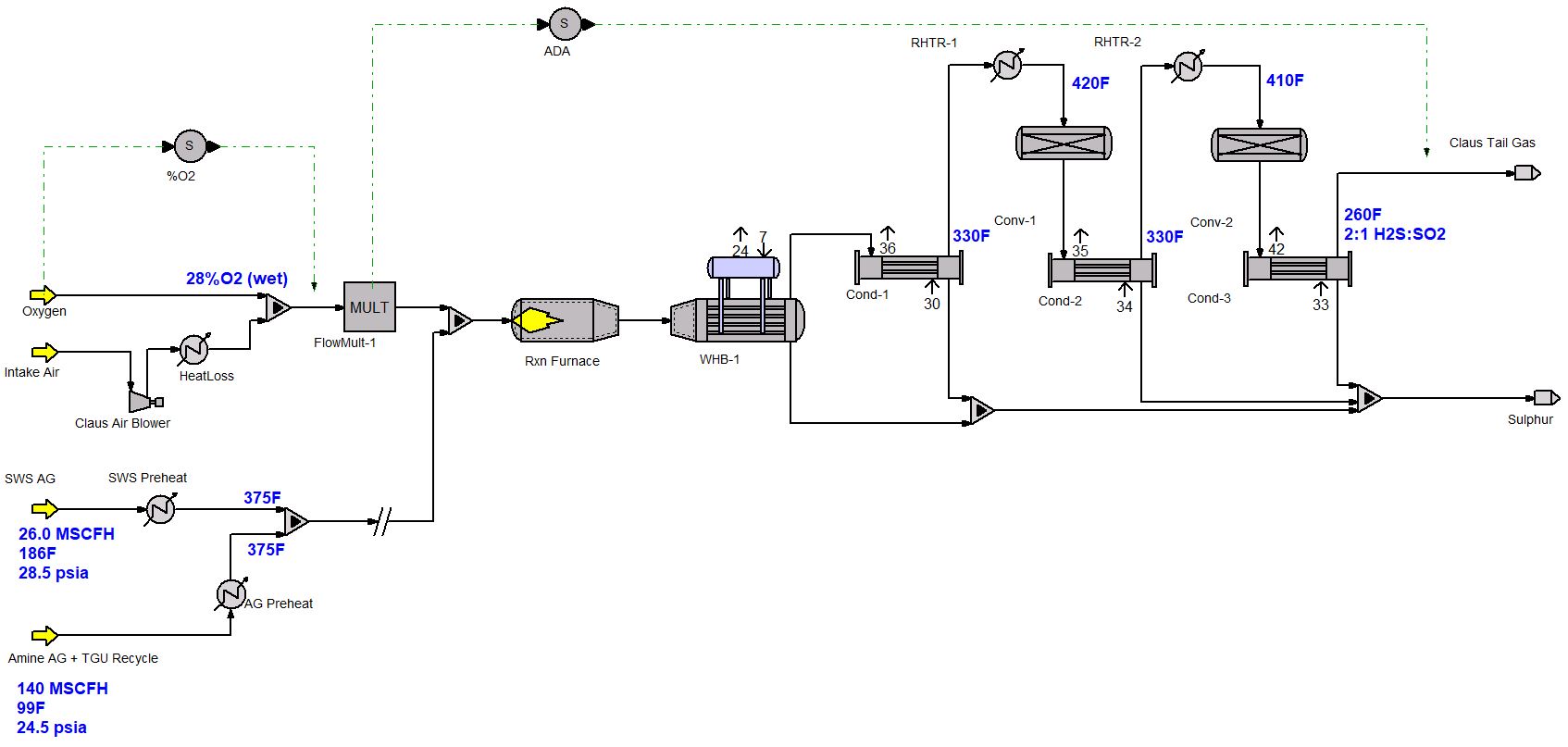

SulphurPro® lets you build a detailed model of your SRU exactly as it's constructed. This flowsheet shows a two-converter unit with feed gas from an AGRU plus feed from a SWS with oxygen enrichment and combustion air flow controlled by an Air Demand Analyzer. The SRU can be fully integrated with upstream acid gas processing, including AGRU, SWS, AGE unit and integrated with downstream Quench and TGTU, all in one flowsheet.

SulphurPro uses a mechanistic engineering-science approach (not fits to operating data) to simulate:

- Thermal Reactors

- Waste Heat Boilers

- Sulfur Condensers (both Design & Rating)

- Sulfur Converters with Degrading Catalysts (both Design & Rating)

- Reheaters

- Burners

- Detailed Hydrogenation Reactors with Porous Catalysts — Read more→

- TGU quench towers, Acid Gas Enrichment (AGE)

- Stack Emissions

- Degassing Pit

- Sulfidic Corrosion in WHBs

- Oxygen Enrichment

- SO2 Breakthrough and its Effect on Performance

OGT | SulphurPro® allows you to accurately assess faults and non-optimal operating conditions within the sulphur recovery unit to help improve time-on-stream, avoid unplanned outages, plan and prepare properly for turndown conditions, and assess sulphidic corrosion rates to avoid catastrophically expensive WHB failures.